How architecture students created face shields to help those in need.

Students studying architecture at Kansas State University are always looking for new and innovative ways to improve the field of architecture and design. Whether it be through fabrication, exploration or technological innovation, students search for new ways to push the industry forward. However, when COVID-19 impacted the Manhattan community, the architecture students not only were asking, “how can we innovate?”, but most importantly, “how can we innovate while helping our community?”.

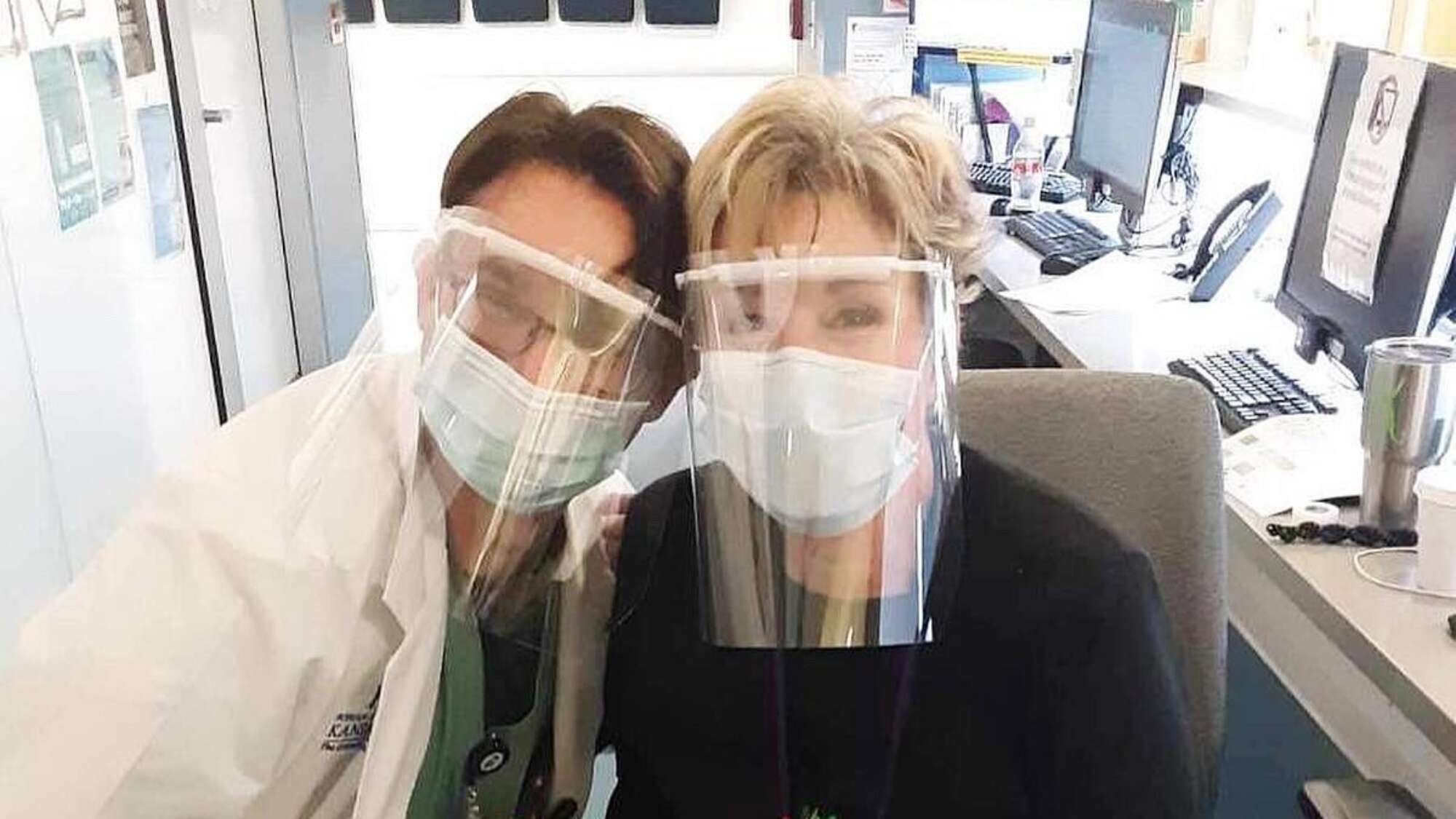

Thus, the students produced their very own face shields with the aid of a 3-D printer. “The students saw through social media and television that other universities, specifically architecture programs on the east coast, had digital files to print and create designs for PPE equipment. This gave them the idea to create face shields for the community,” said Jonathan Dessi-Olive, assistant professor of architecture. Detailed plans for the face shields came from an open-file sharing source. “With the aid of the designs found on these digital files, students were able to research what specifications would work best in the face shields they were going to distribute to the community,” Dessi-Olive said. “The students wanted to be sure that the shields could accommodate everyone. So, once they decided on the design, they modified it so people with glasses could wear the face shield comfortably. We also put a K-State logo on the shield because we wanted to show pride for our community,” Dessi-Olive said.

The face shields are made of many common materials and do not take long to produce. “The students are using the 3-D printers to print the hard plastic for the face shields, as well as printing the transparency sheets, which is the material found on overhead projectors. The shields take between 90 minutes to two hours to produce.”

Dessi-Olive wanted to express his gratitude to the dean of the College of Architecture, Planning and Design, Tim DeNoble, FAIA. “Dean DeNoble has been so helpful with this project,” Dessi-Olive said. “From going to high schools across the region to get transparency sheets to securing additional funding for more 3-D printers, Dean DeNoble has believed in this project from the start, and we are so grateful for his continued support.”

What the students believed to be a local effort to help the community has quickly turned into something far bigger. “We have, to date, produced more than 2,600 face shields that are helping people and local medical clinics across the state of Kansas, as well as other states such as Missouri, Colorado, Nebraska, Florida and New York,” Dessi-Olive said. “It is so gratifying to the students to be able to assist all of these people and medical clinics who, in most cases, are still waiting on this PPE equipment from the federal government.”

This project has been funded by the College of Architecture Planning and Design. If you want support the college, give online.

By James Dalton Burton